From Packaging to Electronics: Superior Carbon and Label Inks for Every Need

In a world driven by rapid innovation across industries from packaging to electronics, the right inks can make all the difference. Advanced conductive carbon inks have become essential in fields such as flexible electronics, sensors, printed circuits, and wearable devices. At the same time, the demand for high‑quality printing in branding, labeling, and packaging continues to rise, making reliable, consistent formulations vital for businesses large and small.

Conductive carbon inks offer a cost-effective alternative to metals like silver or copper, providing reliable conductivity and durability. At the same time, label printing inks ensure vibrant visuals, compliance, and traceability. Choosing the right ink impacts performance, longevity, and sustainability across packaging and electronics applications.

Understanding Conductive Carbon Inks: What They Are and Why They’re Used

Conductive carbon inks are specialized formulations in which carbon particles, often graphite or carbon black, are dispersed in a binding medium to create an electrically conductive coating. These inks are widely used where flexibility, corrosion resistance, and conductivity are required without the expense of metal‑based alternatives.

1. What Makes Carbon Conductive?

Carbon’s unique structure allows electrons to flow along its lattice, enabling it to conduct electricity. While less conductive than metals like copper or silver, carbon offers excellent stability, resistance to oxidation, and performance in applications requiring flexible substrates.

2. Applications in Printed Electronics

Conductive carbon inks are extensively used in printed electronics, including RFID tags, printed heaters, and flexible displays. Their ability to be printed on diverse substrates — paper, plastic, textiles — makes them ideal for rapid prototyping and large‑area electronics.

3. Advantages Over Metal‑Based Inks

Compared to silver or copper, carbon inks are far more cost‑effective, less prone to oxidation, and less sensitive to environmental degradation. They are ideal for applications where extreme conductivity is less critical than stability and cost.

4. Tailoring Performance through Formulation

Manufacturers tweak binders, solvents, and carbon particle size to balance conductivity, adhesion, and mechanical flexibility. A higher carbon loading typically improves conductivity but may affect printability — so formulation is key.

5. Environmental and Safety Considerations

Carbon inks often have lower toxicity and environmental impact than many metal inks. Proper disposal and handling protocols still apply, especially in industrial production, but overall carbon is relatively benign.

6. Emerging Trends and Innovations

Advances in nanocarbon materials such as graphene and carbon nanotubes are driving next‑generation conductive inks. These offer enhanced conductivity and performance in high‑tech applications like sensors, energy storage, and biomedical devices.

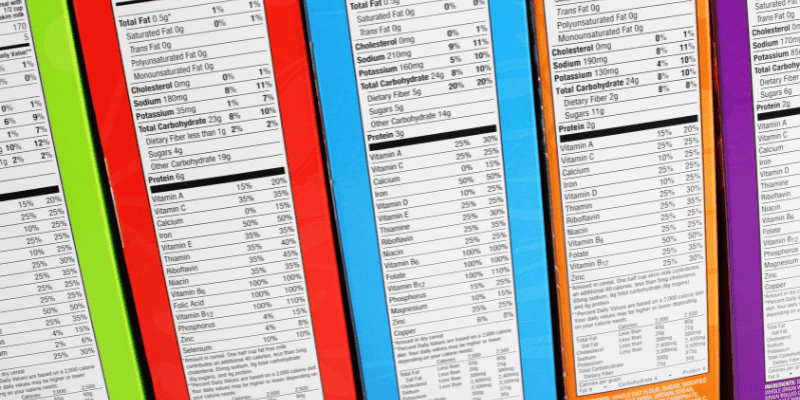

Choosing the Right Label Printing Ink: Many Needs, One Solution

Label printing ink is no longer a commodity; it’s a precision tool that must meet diverse needs across industries — from food packaging to electronics labeling — while balancing cost, print fidelity, and environmental performance.

1. Print Quality and Resolution

High‑quality label printing ink ensures crisp text, vibrant colors, and consistent coverage. This is vital for branding, barcodes, QR codes, and any printed element that must be reliable and legible throughout the product lifecycle.

2. Substrate Compatibility

Different labels require different inks depending on the material — paper, film, fabric, or synthetics. Choosing ink that bonds well with your substrate prevents issues like smudging, peeling, or fading.

3. Durability and Resistance

Label printing ink often needs to endure moisture, abrasion, UV exposure, and chemicals — especially in industries like food, beverage, automotive, or outdoor products. UV‑curable and solvent‑based inks offer superior resistance in harsh conditions.

4. Regulatory and Safety Compliance

In sectors such as food and pharmaceuticals, ink formulations must comply with safety and environmental standards. This includes low VOC emissions, food‑safe certifications, and recyclability considerations.

5. Printing Technology Choice

Different printing systems — flexographic, digital, screen, thermal — require different ink types. Understanding your printer’s requirements ensures optimal performance and minimal downtime.

6. Cost vs. Performance Balance

While premium inks provide enhanced performance, balancing your budget with performance requirements is key. Often, a slightly higher ink cost yields better long‑term value through reduced reprints and fewer returns.

Key Factors in Ink Selection and Application

Selecting the right ink involves more than just conductivity or color. These considerations help ensure performance, longevity, and cost‑effectiveness.

1. Purpose of the Final Product

Start with the end in mind: Is the final goal decorative, functional (like conductivity or resistance), or regulatory compliance? The purpose dictates formulation choice.

2. Environmental Conditions

For outdoor or industrial use, inks must withstand humidity, UV light, temperature swings, and physical wear. Interior applications may prioritize aesthetics and quick drying.

3. Application Method

Whether screen printing, flexography, or digital printing, the application process determines viscosity, drying time, and binder selection.

4. Substrate Material

Plastic films, papers, textiles, and metals all interact differently with inks. Choose formulations that chemically and mechanically bond with your substrate to avoid peeling or cracking.

5. Durability Requirements

Functional inks like conductive carbon must maintain performance over time without degradation, while label printing inks must retain readability and color fidelity.

6. Cost of Ownership

Beyond the upfront price, consider maintenance, failure rates, rework costs, and waste. High‑quality inks often reduce total cost of ownership through better performance and fewer defects.

Understanding Black Carbon Price & Its Impact on Inks

The cost of carbon materials, often reflected in black carbon price, influences ink formulation costs and market pricing. Black carbon , a key component of many conductive and pigment inks, varies in price based on purity, particle size, and production method.

Manufacturers balance performance requirements with economic feasibility. Higher‑purity carbon with consistent particle size yields better conductivity and color strength but comes at a premium. Conversely, lower‑grade carbon may reduce material costs but compromise performance. Understanding price dynamics helps businesses forecast costs, optimize ink selection, and plan long‑term procurement strategies.

Conclusion

Whether you are producing intricate electronics or vibrant product labels, ink choice matters. High‑performance conductive carbon inks deliver dependable electrical pathways, while premium label printing ink ensures lasting color, clarity, and durability. Considering factors like substrate compatibility, environmental resistance, and total cost of ownership leads to smarter, more sustainable decisions.

For reliable and innovative ink solutions across industries, Birla Carbon offers high‑quality carbon materials that support advanced conductive inks and pigment formulations. Their products help manufacturers optimize performance while managing cost pressures influenced by black carbon price trends.